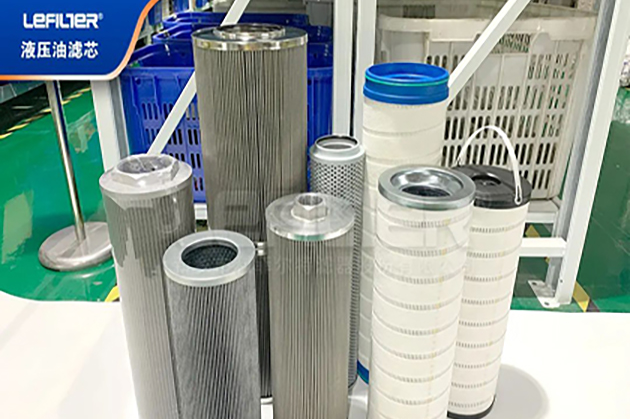

Hydraulic oil filter elements are mainly made of glass fiber filter paper, chemical fiber filter paper, wood pulp filter paper, stainless steel braided mesh, sintered mesh and other filter materials and single or multi-layer metal mesh. In specific use, its number of layers depends on the composition of the mesh. The number of meshes depends on different usage conditions and purposes.

Correct use of hydraulic oil filter element?

First drain the original hydraulic oil in the tank and check the hydraulic oil filter element to see if there are iron filings, copper

filings or other impurities attached. After maintenance and removal, clean the system.

Identify the grade of the hydraulic oil. Mixing hydraulic oils of different grades and brands will cause the hydraulic oil filter

element to react and deteriorate to produce floc.

The hydraulic oil filter element must be installed before refueling. The pipe mouth covered by the hydraulic oil filter element

leads directly to the main pump.

Do not let the oil in the tank come into direct contact with the air. After adding oil, be sure to drain the air from the main pump.

The way to drain the air is to loosen the pipe joint directly at the top of the main pump and fill it up directly.

Check the oil quality regularly. The hydraulic filter element is a consumable item and needs to be replaced immediately if it

becomes clogged. Pay attention to flushing the system oil tank and pipelines, and when refueling, use a refueling device with

a filter.